E=MS²: Management Software for Cost-Efficient Energy Routing

Energy costs have become a significant portion of OPEX for food production companies, alongside growing concerns over the environmental impact of energy consumption. Our project E=MS² addressed these challenges with an innovative digital solution to optimize energy use during food processing operations.

Challenges addressed

Energy markets are increasingly affected by fluctuations in supply and demand, causing imbalances and extreme price volatility. Consumers face sharp price swings and even negative tariffs for feeding power into the grid.

A sustainable response is to maximize on-site use of self-produced energy. By smartly aligning production and consumption with forecasting, digital control and buffer capacity between electrical and thermal energy, companies can lower costs. This approach also prevents the need to switch off energy production (curtailing) and contributes to a more stable energy system.

Solution

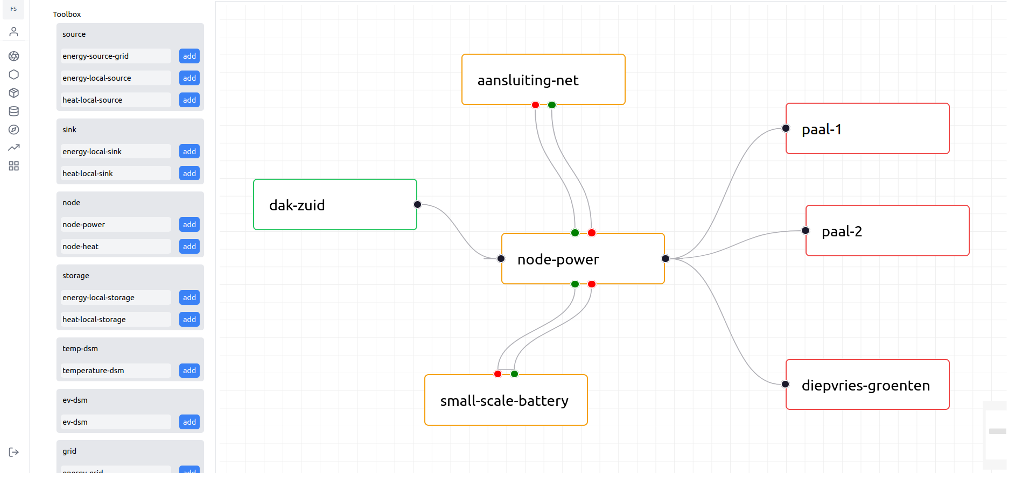

By creating a digital twin of a food processing company (Horafrost) and integrating AI-based optimization tools, the solution translates data into automated, smart actions. Using freezer storage spaces as thermal buffers to bridge unfavorable fluctuations in electricity prices.

A key feature is leveraging deep-freezing variables to buffer energy, benefiting multiple zones. Improved energy consumption predictions for large users also help energy suppliers balance purchase volumes effectively.

Impact

The forecasting model brings a better control of the freezing unit. Measuring is not instant but based on evaluation of historical data.

The software setup holds the evaluation of both costs: original and new; and provides this as an outcome for the client. This will result in financial savings up to 20% and energy savings up to 10%

This project demonstrates the strength of combining the complementary expertise of PropheSea and Ikologik, with each contributing their unique capabilities to create an innovative energy management solution for the food processing sector.

Ikologik leverages its deep knowledge in data integration to seamlessly gather and unify complex operational and energy data from food processing environments. This solid data backbone enables precise and reliable digital twin modeling of energy consumption and production.

Meanwhile, PropheSea applies its expertise in advanced artificial intelligence algorithms to analyse this integrated data, extracting valuable insights and accurately predicting future energy demands. Their smart decision tools empower food processors to optimise production timing, reduce costs and maximise the use of locally generated renewable energy.

It is expected that arriving at the new situation, more optimization possibilities will be revealed and added to the model. Again, simulation of before and actual situation can be done in the software. Analysing the actual energy usage is a strategic project at Horafrost. This will bring insight to other areas where the model could be applied, and energy savings can be obtained.