Implementation of Computer Vision and Data Modelling: 2 use cases

Orise has customised its state-of-the-art AI software "Yanomaly" for detecting product and process deviations to the needs of the food industry. The solution has been developed for 2 use cases: inline quality control of potato mash processing and product anomaly detection at Pomuni and groundwater and energy monitoring at Brewery De Brabandere. This 1,7 mio € investment project will result in higher production efficiency, reduced food waste, lower consumption of energy and water and greater customer satisfaction.

Challenges addressed

Implementing Computer Vision and Data Modelling

Orise is a state of the art software leveraging AI to support production and maintenance teams by reducing energy and raw material consumption, minimizing waste, and increasing efficiency. The challenge for Orise in the HIGHFIVE project was the implementation of 2 use cases in the food industry, demonstrating how smart software solutions can contribute to a greener and more profitable future.

Inline monitoring and quality control of potato mash “dry matter”

The “dry matter” balance of potato mash is a crucial quality indicator for the processing of potato products. In order to keep it a required target level, the operator will decide if needed to add starch flakes during the production process. For this decision, the operator will rely on a hourly lab measurement (off line). Imagine 1 hour of inadequate production.... An AI based model to predict the dry matter content will enable faster decision making and will ultimately lead to more efficient production and reduction of food waste.

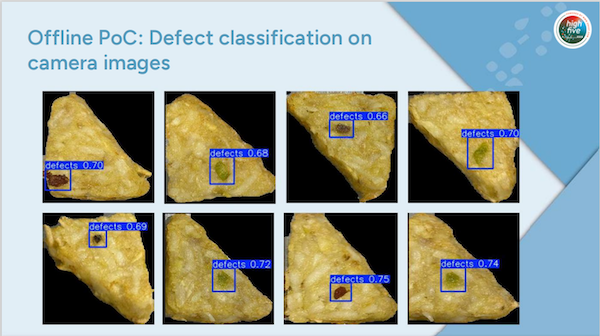

Computer Vision for anomaly detection on hashbrowns

Pomuni also wants to detect product deviations and anomalies during the production process: presence of foreign objects, presence of baking crumbs, deviations in colour and/or shape. The early detection of product deviations will improve product quality , reduce waste and objectify quality discussions with BtB customers

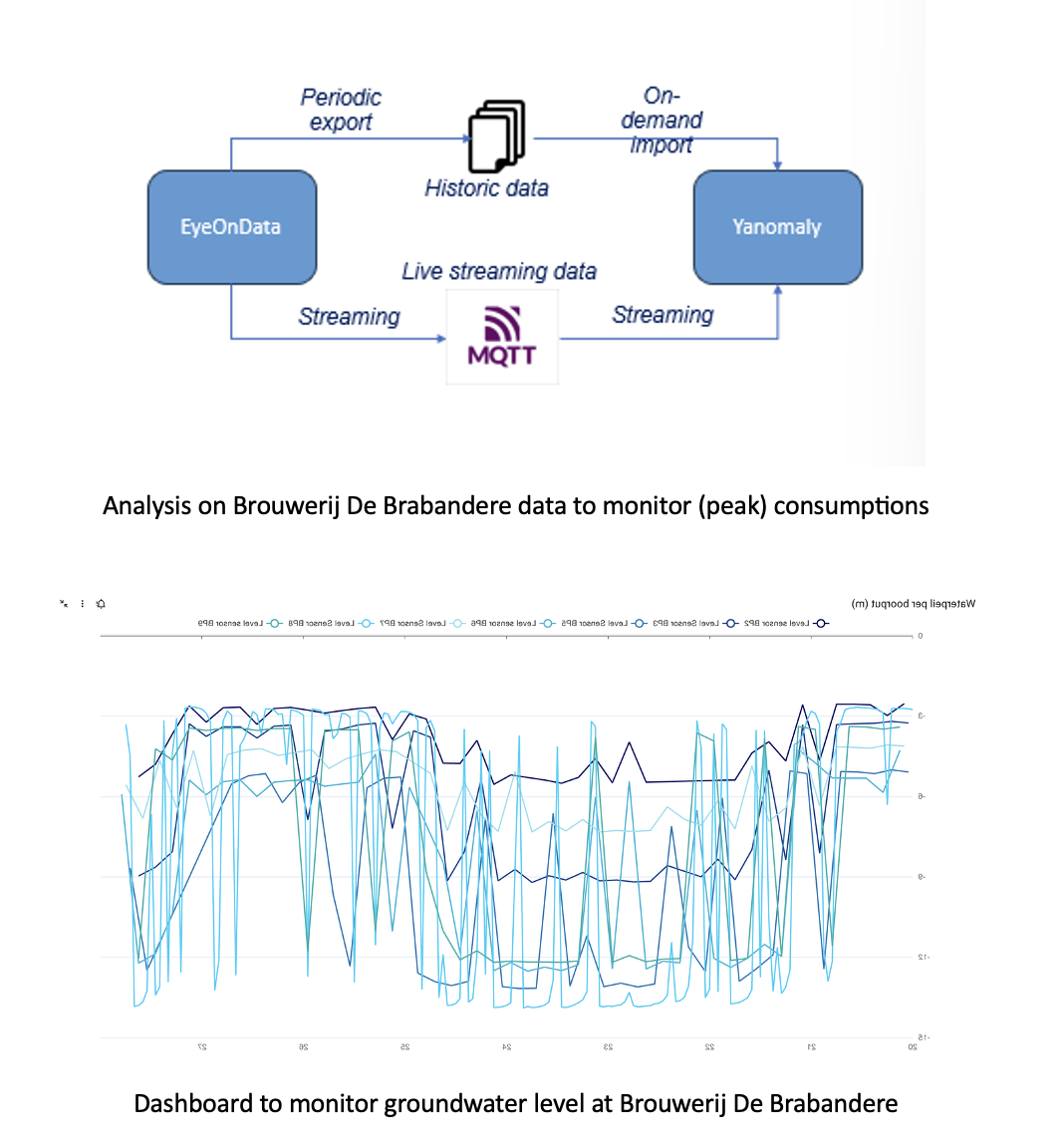

Predictive modelling for groundwater levels

Underground water from wells normally provides the best water quality in terms of microbiology and organics. These characteristics mean a competitive advantage and therefore Brouwerij de Brabandere wanted to better manage the continuous supply of groundwater from the wells. As climate change is causing more often and longer periods of drought, the advanced monitoring and level prediction of the 7 water wells at brewery De Brabandere is of strategic importance. It will make production more robust and agile to switch whenever needed to city water.

Integrated resource (energy, water) management

Energy dashboards are quite common in the brewery sector. But BDB wanted something more integrated to monitor both energy and water consumption . Therefore the monitoring of the data of water consumption, next to the energy consumption, needed to be automated.

Solution

The applied digital technologies (sensor technology, computer vision, data capturing & analysis including AI), will turn the sensor and camera data via online dashboards into insights and actions for operators and operational management.

Yanomaly software was used to monitor the production process of potato mash and predict product quality characteristics to support the operator in the ongoing decision making. The introduction of a „virtual lab“ during the production process will be a real breakthrough for inline quality control of food processing.

Orise built a computer vision-based measurement and detection solution to monitor deviations and anomalies in hashbrowns at the exit of the oven. This will enable corrective measures before the packaging and delivery of the final products .

The monitoring and level prediction of the water wells at Brouwerij de Brabandere is a strategic puzzle piece and will contribute to a fully integrated monitoring of energy and water consumption.

Impacts

The prediction of the dry mass percentage in potato mash at Pomuni looks promising and can be considered as a real breakthrough innovation in the online quality monitoring of food processing. The use of more qualitative data sets and the continuous matching with lab measurements turns the “Yanomaly” predictive modelling tool into a virtual lab with online access for the operators. This will result in more stable product quality and food waste reduction.

The initial energy and water consumption savings at Brouwerij De Brabandere confirm the significant potential for a more sustainable resource management (operational efficiency, environmental impact) in the European SME beverage sector. The advanced monitoring and level prediction of the 7 water wells at brewery De Brabandere will make production more robust against long periods of drought.

While initial results and feedback for both use cases are promising, the quantification of the expected value creation will be available as of 2026.

Anomaly detection with computer vision measurements at Pomuni.

What's next?

Orise

Orise Digital AI" (formerly Yanomaly) is designed for real-time, large-scale monitoring and optimization of machinery and production workflows. Further development will continue within the different business units of Orise. The extra development and added features during the HIGHFIVE project, make the existing AI based software easily adaptable for other food processors. This will be evaluated within the European Food & Beverage business unit of Orise.

Pomuni

The dry matter monitoring innovation has triggered the management to continue the development of the virtual sensor potential. We want to gain a better insight and understanding of the potato product specifications. For example:

- what is the influence of holding time on dry matter within the spiral freezer?

- what is the lowest level of dry matter that cannot be compensated anymore with potato flakes.

- what is the cost difference between potato flakes and potatoes with higher dry-matter content?

A new vision project has been launched in collaboration with Orise (Yazzoom) to inspect emptied boxes of semi-finished products. The goal is to determine whether the boxes meet basic reuse requirements, allowing them to be used again without washing. This approach helps save water, energy, and chemical agents, reducing both costs and environmental impact.

Brouwerij De Brabandere

The results off the HighFive project will stimulate to optimise water and energy usage in the future. The outcome of the project is an important stepstone for the development and future implementation of renewable energy (solar panels and biogas) in the brewery.

The management will continue the path off digital innovation in all departments and already hired a head of digital innovation to help in future projects.